60 Seconds of Skill: Sheffield knife-maker Michael May

60 Seconds of Skill is a moment to reflect, a minute from the ads to take a break and watch Craftspeople from the UK make some beautiful objects. Often these items are made in the same way that they have been made for hundreds if not thousands of years. They remind us that History is Alive. This time we talk to Michael May a Knife maker from Sheffield. We talk about it’s history, reputation and innovation.

How to make an impressive pocket knife

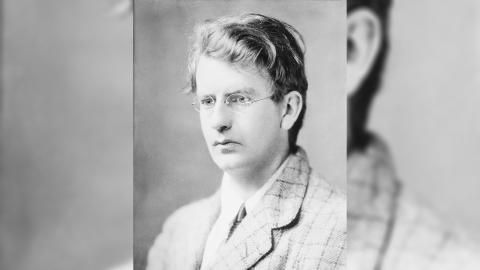

Michael May never knew he wanted to be a knife maker. After leaving music college, Michael was looking for work. Following other family members into the Sheffield cutlery trade, he got a job in a cutlery factory. After various roles, Michael found myself in the pen and pocket workshop, where he stayed for three years before leaving to study history at university. Two degrees later, he was back making knives. Under Keith Moorby, Michael learned how to craft knives to the highest standard and he realised that this was what he wanted to do for the rest of my life. Over the years, more and more people would ask him to make a knife for them, impressed by the high level of craftsmanship.

How did you get into knifemaking?

I wasn’t intending to set out as a knife maker. I had just left music college and was looking for some work. My sister-in-law worked in a cutlery factory and said they had a job going there. I did various jobs around the firm and ended up in the pen and pocket knife department and enjoyed making knives there. Up until then, I hadn’t realised how much I enjoyed using my hands to make things! After leaving to go to university I went back to the firm and continued making pocket knives until 2016 when I left to set up my own business.

You are based in Sheffield, how long have Knives and Cutlery been made there?

The first reference to Sheffield cutlery was recorded in the 13th century. Chaucer also references a Sheffield knife in the Canterbury Tales. The seven hills and five rivers of Sheffield ensured that it had an abundance of waterpower, wood for charcoal and coal, making it possible to manufacture knives and cutlery.

How important is it that you continue to make Knives from Sheffield steel in Sheffield?

Sheffield is known throughout the world for its steel and cutlery. I am working off the back of a reputation that was gained centuries ago. I hope people who see my work would think ‘it must be decent – it’s from Sheffield!’.

How many people still craft Knives and Cutlery in Sheffield? Are we in danger of losing that UK based trade?

I know of a couple of companies that still make hand-crafted knives in Sheffield. We are on the endangered list, but I think it will always survive here. I have an apprentice who is 23, and I’m sure there will be more as the business grows.

Do you still use traditional processes in the creation of your Knives?

I would like to think that if I was put in a workshop in 19th century Sheffield, I would be able to make the same product that I currently make. The power to the machinery is different, but essentially the process is pretty much the same. The main motor I use for the belt grinder was bought from Trevor Ablett and dates back to the 1930s and is still doing the same job as it was back then.

How long does it take to make a Knife like the one you did for 60 Seconds of Skill from start to finish?

The Clayton Barlow knife that is made in the video would probably take a few hours to make. It can take several days to make all the templates for the particular pattern, and after trial and error, it should be pretty straightforward after that, although the handmade element does mean each knife is different and thus doesn’t always behave!

What style of Knife is this and what other kinds do you make?

The Clayton Barlow is a knife I designed based on a pattern made by Sheffield cutler Graham Clayton who produced some of the finest knives ever made in Sheffield in my opinion. The Barlow knife was first made in Sheffield in the 17th century and has been a staple ever since.

Sheffield has a long tradition of knives/patterns that are tried and tested, so I try and stay as close to these designs as I can. Sheffield also has a long tradition of innovation, so I try and use this with my designs too. I’m always looking for something new and different I can add to the design of the knife to set it apart from other knives.

How can someone get started in knifemaking? Do you need to have a background in Blacksmithing?

The basic equipment needed to start is pretty minimal. If you had the time and patience, you could make a knife just using hand files. I started in my workshop with the aforementioned belt grinder from Trevor Ablett, along with a drill press, vice, and some parts, which enabled me to essentially pick up where Trevor left off.

I have no experience in blacksmithing. Here at Portland Works, there are two forges which is handy so I leave any forging that needs doing to those guys.

Any famous owners of anything you have made?

George Clarke has bought several from me and even popped into the workshop to pick a knife up. Ben Fogle also bought one from me. I have also had a knife sent to Sandringham, but I don’t know who the recipient was!

How has the pandemic affected your business? What changes have you had to make?

I had to stop work for a little while as I had to stay home and look after my 2-year-old as my wife was working from home. I had people get in touch and want to put orders in even though I wasn’t able to make anything at the time, just to help support the business. I saw a gained interest in independent businesses and people looking to support these.

What plans do you have for the future?

Having moved into a bigger workshop, I have the space to keep expanding. I’m always looking to try new designs and expand the range. I’m hoping to be able to employ more people and help pass on the skills and knowledge and keep the trade alive in Sheffield.